We keep things moving

AMT Schmid GmbH & Co. KG is an innovative, healthily grown, medium-sized company. For over 40 years, we have been developing and producing standardised industry and customer-specific drive solutions with a clear goal: To restore mobility for people who are restricted in their freedom of movement and opportunities.

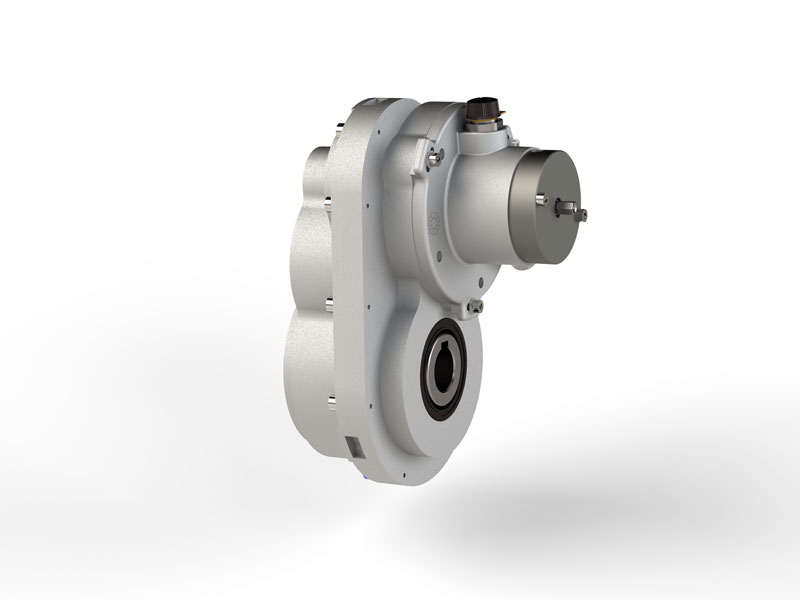

With our battery-powered applications, we are the European market leader and we operate globally. Our product portfolio includes electric motors, gearboxes, electromagnetic brakes and customised special drives. Primarily, we operate in the healthcare sector. Our special drives in particular are also finding their way into countless other areas of application.

Everything from a single source

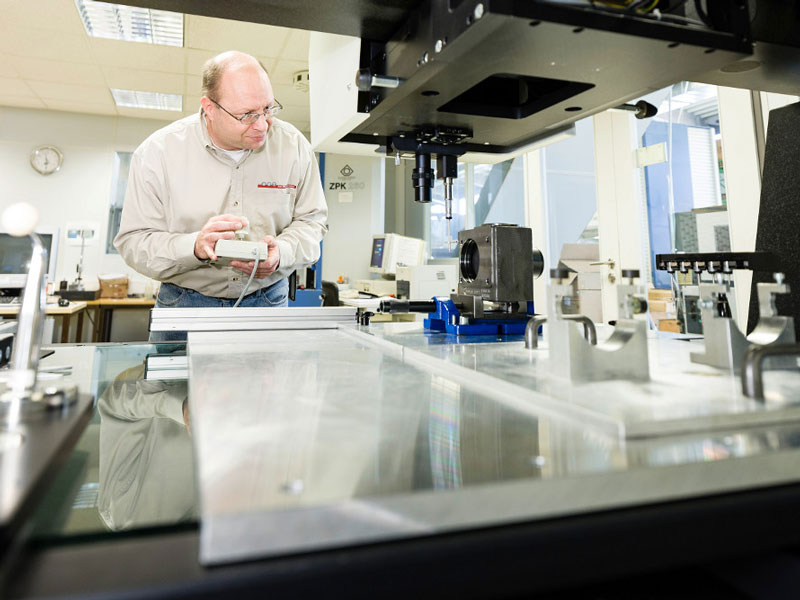

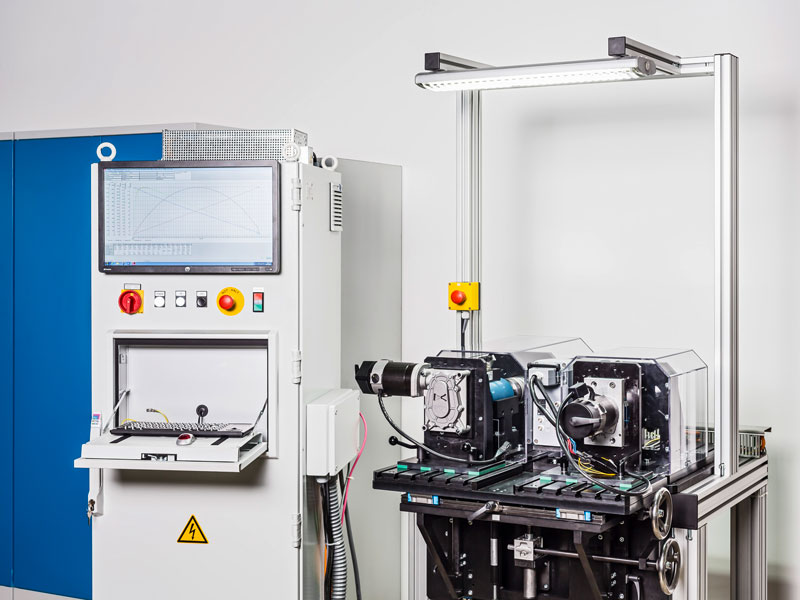

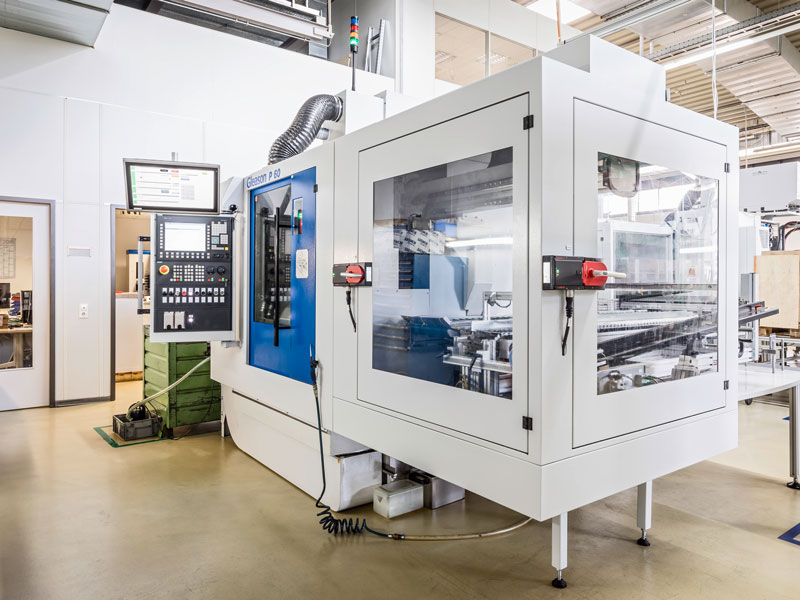

The large vertically integrated scope of manufacture at AMT enables us to achieve consistent quality assurance while assuring optimum cost-effectiveness and maximum flexibility. Our aim is to move even more for you. In this way, we consistently gear our performance to the wishes of our customers and we are only satisfied once you are delighted. The outcome of this partnership takes the form of innovative drive solutions that can cope with any everyday requirements. We give you our word on that.

Our philosophy

„We are not satisfied until our customers are delighted. That’s why we move more than is expected of us.“

This philosophy – this principle – drives us in all areas. Be it in strategic planning, company management, daily production or, of course, in service to our customers, partners and clients.

In short:

- We are expanding our company meaningfully and consistently

- We develop optimum product solutions for the benefit of our customers

- We always strive for the best, especially in cooperation with our customers

- We stand for excellent quality in all areas

- We pay attention to reliability and keeping agreements

- We move more than our competitors

Environmental and climate protection

Beyond the legal requirements of environmental law, AMT Schmid is careful to act in an ecologically sustainable and responsible manner. We are efficient in our use of energy and resources, and strive to produce as little waste as possible. We promote the environmental awareness of our employees and suppliers. We expect our employees to act responsibly in the manufacture and distribution of our products and/or services. For the protection of our employees, we observe all laws and rules pertaining to health and safety at the workplace.

Become an AMT supplier

We see our suppliers as partners who contribute significantly to the global success of our drive solutions. That is why we place the highest demands on them as well as on ourselves.

We rely on innovative, high-performance partners with high quality awareness, good delivery capability and competitive prices. Our goal is a long-term cooperation based on partnership and successful for both sides.

If you are interested in working with AMT Schmid, please apply here.

Essential requirements for our suppliers are:

- High quality standards

- Assured quality processes

- Certification in accordance with DIN EN ISO 9001:2015

- Flexibility

- Short delivery lead times

- Competitive prices

- Acknowledgement of our Terms and Conditions of Purchase and our Code of Conduct

- Compliance with our delivery guidelines

- EDI (Electronic Data Interchange)

- Environmental Management System DIN EN ISO 14001:2015

Code of Conduct

Our Code of Conduct sets out, in addition to our values, which principles of conduct and standards are relevant and binding for us. This applies to dealings with employees, customers, suppliers, business partners, the environment and society. It serves as a guideline for ethically and morally sound, value-oriented action that is compliant with the law and regulations.

You can find our detailed Code of Conduct here.

Terms of contract

You can find our terms of purchase here: